Joining forces, Aviapartner, Air Cargo Belgium and Iristick are on a mission to innovate the airfreight industry by creating a more efficient way to accept, check and handle shipments at BRUcargo with the help of smart glass technology. To achieve this goal, all partners are cooperating together with VLAIO, who granted and funded this project, to develop and test the proof-of concepts.

How will smart glasses operate during the acceptance check process?

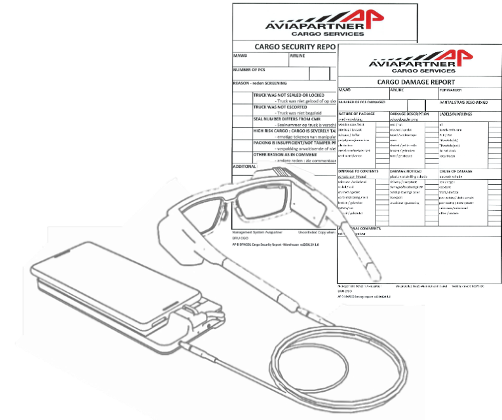

When freight forwarders deliver export freight at BRUcargo, the operational team of Aviapartner will be assisted by the smart (safety) glasses, provided by Iristick.

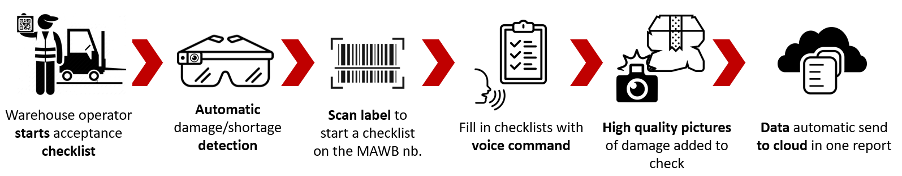

If damage or shortage is detected during the acceptance check, the warehouse operators can automatically start a checklist by scanning the MAWB number without the need of paper-based documents, nor handheld devices. Operating on voice command, the smart glasses help to fill in the checklist and allow for high quality pictures to be taken and added to the checklist’s report. After the checklist is finished, data are sent live to the cloud.

A visual representation of the ideal scenario we are aiming to create:

Testing Phase successfully completed

This month, a new milestone in the project was reached by testing and validating these two new proof-of-concepts. The first proof-of-concept focused specifically on digitising the acceptance checklists for damage and shortage and is currently passing the testing phase. The second proof-of-concept aims to improve handling processes by automating shipment’s label recognition through the use of Artificial Intelligence (AI) and has almost finished its first development sprint.

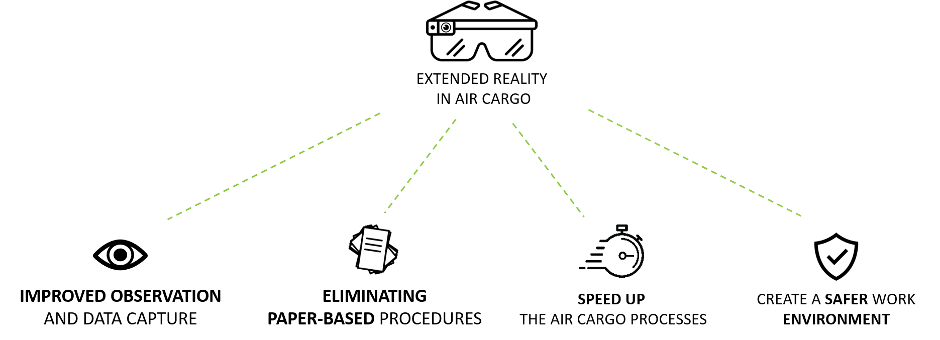

Using the right testing criteria

Targeting to innovate and improve the current operational processes in the air cargo industry, the proof-of-concepts have the potential to tackle multiple manual tasks and procedures within the ground handling agent’s operations. To evaluate the potential future value of this smart glass technology, field testing was based on four specific criteria as presented above.

Based on the gathered feedback from the testing week, we aim to create a future proof scope that allows for a more efficient handling process. Hopefully, this new XR technology can change the future in air cargo.