Industrial smart glasses can be used for several use cases. Besides enabling a real-time video conferencing connection between two parties at different locations (also known as remote assistance), smart glasses also help transform industry floors by digitalizing what once were cumbersome, printed out and outdated procedures and work instructions. These paper-based work instructions are thus transferred into digital form and centralized in a robust all-in-one guided work instructions management tool. It goes without saying that these digital work instructions guidance are gaining immense popularity thanks to their multitude of advantages. Besides lifting the deskless workforce to the next level, these step-by-step visualizations of complex processes are facilitating and simplifying industrial processes as a whole.

The role of machines and operators

Whether a company or factory is active in manufacturing, assembly, process industry, pharma or utilities, ensuring machines work errorlessly and safely with minimal downtime is number one priority. End products are often completely made by assets, robots and machines, whether it be through flow operations, batch operations, a mix of both or entirely via continuous product control and inspection. While it may seem that machines do the heavy lifting, technicians, operators and engineers play a crucial role in guaranteeing product quality and continuity. They perform supporting activities such as quality and product inspections at the end of the line in addition to ensuring the optimal functioning of the installations and machines.

Paper-based SOPs are often outdated, inconvenient and obsolete

For supporting activities such as maintenance support, quality control, logistics operations and field services, enterprise operations often consist of executing a set of consecutive and standardized steps, depending on the specific use case. Up until now, paper-based workflows or instructions were the norm. These guidelines and instructions, often referred to as Standard Operating Procedures (SOPs), would be printed out and provided to the operator or technician executing the steps.

Although this rather old-fashioned method of working is still at par, it comes with a handful of complications: printed out SOPs are hardly updated, often implying a cumbersome work method whereby the executed workflow does not match the real workflow. There is no execution trace so falling back on historical data is impossible. Also, there is no option to personalize instructions in terms of skill level. A senior, who has been executing the steps for years and who knows the instructions fairly well, receives the same content as a junior, leading to inefficiency. On top of this, there is no to very limited feedback between the operator and the supervisor or manager. As this one-way work method does not make it possible to register details or data, the communication remains static and non-interactive. And finally, as the executed work is not being captured or logged, no one can really check whether all steps have been executed correctly, again lacking in traceability and jeopardizing compliance. As a work method inherent to multiple flaws and inconveniences, the need for a digital work instruction platform is now more than ever topical.

Digital work instructions: transforming SOPs forever

Digital work instruction e platforms, such as the Proceedix platform, let you easily manage enterprise procedures, work instructions and inspections in a digital admin platform. These instructions can be executed by field workers and technicians with the use of tablets, smartphones and smart glasses.

Digital or visual step-by-step work instructions are brought into life to make sure the job gets done the first time right. Imagine a digital workflow specifying the tasks that you should do, just like a routing formulates the manufacturing steps of a product. Rather than extensive descriptions for each task, the instructions need to be formulated short and “snackable” in the blink of an eye. This type of task flow can be processed on a mobile phone or on the small display of smart glasses. If the device automatically records the operator's activity and feedback, there is indisputable proof of execution. Moreover, the structured data logs can be exploited by business analytics and act as a perpetuum mobile for continuous improvement. This is the structure and mechanism of a digital workflow execution platform like Proceedix.

Digital work instructions on smart glasses: the best combo

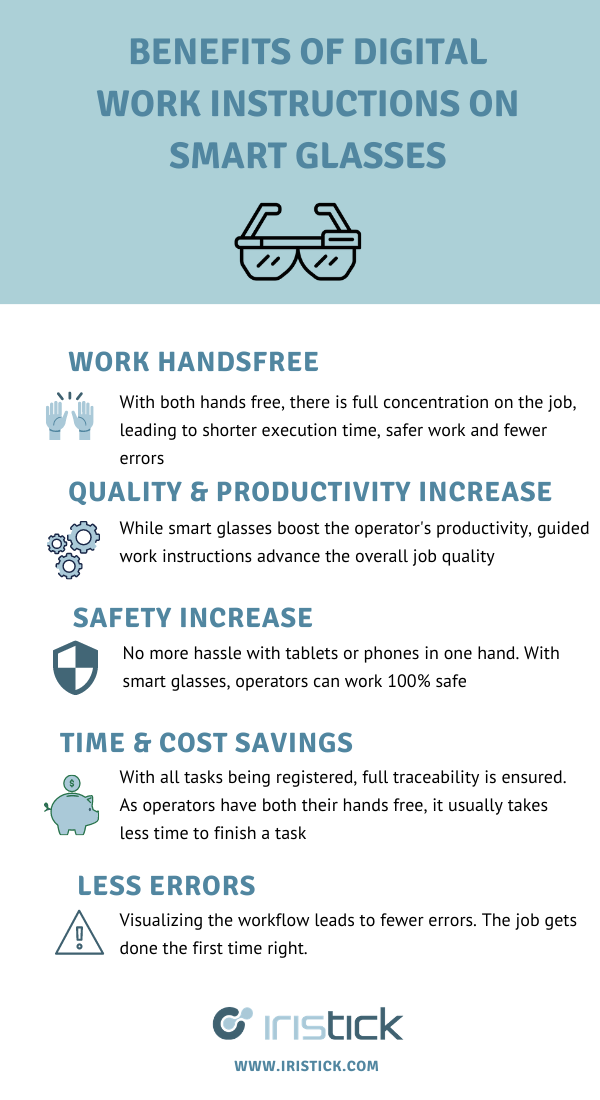

As work instructions, workflows, checklists and inspections are perfectly executable on mobile phones and tablets, smart glasses have proven to be more effective in the guided work instruction process. The biggest benefit is undoubtedly having both hands free to do the job, leading to higher concentration and in turn, to fewer errors, higher safety and more productivity. Instructions are shown on the small display of the smart glasses and this works in combination with voice commands, really having both hands free to completely focus on the job.

On the shop floor or in warehouses, you want your hands free and eyes on the job. There is a need for an unobstructed view of the wearer and for this reason, smart glasses should opt as safety glasses, with the option to move the small display on the glasses out of the wearer’s sight. Other differentiators to look out for smart glasses-driven work instructions are the weight and comfort to wear the glasses for a full work shift and battery power. Besides this, the number and position of cameras also play a role in deciding whether or not to opt for visual work instructions executed on smart glasses.

Proceedix lets you create easy step-by-step work instructions for your deskless workers

Our software partner Proceedix offers a robust, all-in-one platform that allows to create step-by-step work instructions, workflows, checklists and inspections for your deskless workers. Easily manage workflows on the shop floor, in a lab or in the field. Get rid of paper-based SOPs and visualize workflows, gaining efficiency, productivity and fewer errors. Next to having full traceability, facilitate the jobs of operators and technicians, whilst being 100% compliant with company policies.